-- Silixa, an award winning company that develops and commercialises the next generation of fibre optic sensors, has released more information about distributed sensing.

So, what is distributed sensing?

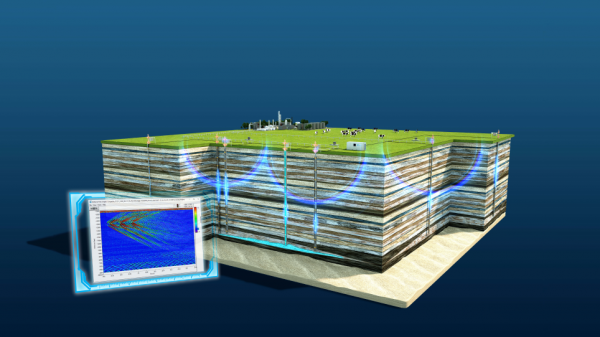

Distributed sensing is the term given to technology that enables continuous, real-time measurements along the entire length of a fibre optic cable. Unlike the traditional sensor, distributed sensing does not rely upon any manufactured sensor, but instead utilises the optical fibre itself.

The optical fibre is made of pure silica and is as thin as one human hair. This discreet fibre consists of the inner core and the outer cladding. The cladding is the glass layer made of lower refractive index glass that allows the light to be maintained within the core. Both the inner core and outer cladding are encapsulated by multiple layers of polymer coating, making it durable as well as easy to handle.

There are two main types of optical fibres, according to communication application standards. These are the single mode, intended for long haul communications, and multi-mode for short-haul communications. Multi-mode fibres have a larger core (45 to 50 microns) than single-mode fibres (8-10 microns), allowing more light modes to propagate.

Although Silixa’s temperature and acoustic sensors can be used with either single-mode or multi-mode fibres, the performance of the temperature system is optimised when it is used with multi-mode. The performance of the acoustic sensor is optimised with single-mode fibre.

Distributed sensing was developed primarily for the oil and gas sector, to help reservoir engineers in optimising well lifespan. They now have a wide range of uses as integrity monitoring instruments in process vessels, storage tanks, and piping systems, providing operators with tools to schedule maintenance programmes and maximise service life.

To find out more about Silixa and to see its post about this subject, see the following URL: https://silixa.com/resources/what-is-distributed-sensing/

Release ID: 89058000